Fabric expansion joint

Application

Fabric expansion joints absorb movements, oscillations and vibrations in the axial and lateral direction in pipelines. Due to the high elasticity and technical characteristics, it is possible to reduce by the incorporation of the fabric expansion in temperature and pressure fluctuations. The fabric expansion joints cover a wide range of applications. Typical applications for fabric expansion joints are gas- and air pipelines, gas cleaning systems of technical systems, induced draft- and gas turbine systems. Temperature and corrosion resistant fabric allows the use of expansion joints for such media as air, flue gases or dusty media such as coal dust or ash.

Video about the production of fabric expansion joints

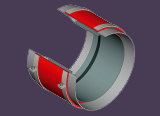

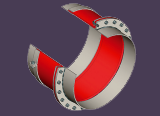

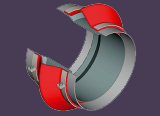

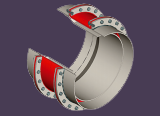

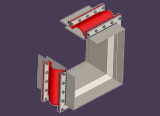

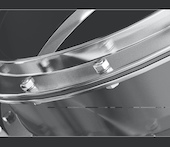

Structure of fabric expansion joints

Fabric expansion joints are made from the layers of thermally insulating and gas-tight materials. The choice of material depends primarily on the location and operating conditions (temperature, pressure, medium). The heat insulating layers are used for temperature reduction in flow media. The temperature drop takes place thanks to high-quality heat-insulating fabric based on E-glass or ceramic fibers.

Another important property of the fabric expansion is the gas-tightness, which is achieved by means of special abrasion resistant coatings on carrier layers. Fabric expansion joints for non-aggressive media are made of fabric with silicone, Hypalon or NBR coating. For flue gases and chemically aggressive media we use fabric with PTFE coating. All materials used in the production of fabric expansion joints are made of fire-resistant and refractory materials, which ensure safety and gas-tightness during use.

Operating for exhaust gases can reach up to 500 ° C, while the flange is used. For higher temperatures or in dusty media we produce fabric expansion joints with internal insulation. Thanks to the flexible materials, it is possible to produce the fabric expansion joints in different geometric shapes and sizes.

Objects gallery

Operating conditions

• Operating temperature: -40°С up to +1200°C

• Operating pressure: -100 up to +300 mbar

Compensation capacity:

• axial: up to - 250 mm

• lateral: up to 200 mm

Mounting:

• Flange

• Hose clamps

Benefits

• High compensation capacity

• Small weight

• All size and forms possible

• Easy replacement

Configuration and selection of fabric expansion joints

For the configuration and calculation of fabric expansion joint we need all information about dimensions and operating conditions. Send us the information you have, so that we can work out an optimized solution including prices, delivery times and technical drawings.

Additional information

Benefits of fabric expansions joints Powerz - compensation capacity in all directions simultaneously.

Types of fabric expansion joints

In the table, fabric expansion joints are listed that differ by fastening. We offer fabric expansion joints with round and rectangular cross-sections of the ducts. We combine innovative technology with our experience and can also produce fabric expansion joints with transitional cross-sections, for example, round to square.

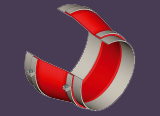

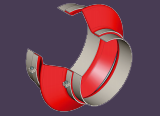

In order to increase compensation capacity, we manufacture fabric expansion joints with shafts or bellows. Thereby, the axial compression go up to 50%.

For important feature of the fabric expansion joints heard high expansion in the lateral direction. The fabric expansion joint Powerz can compensate for up to 100 mm.

+49

+49